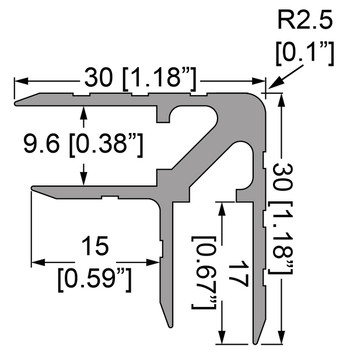

Description

Double Angle Corner Extrusion. Double channels not only make assembly faster and easier, but provide maximum strength and integrity for case framework. See our cutting tips video tutorial

NOTE: Mill finish unanodized extrusions can commonly incur surface abrasions during shipment from rubbing together if they incur harsh handling during the shipment process. This is not abnormal, and is easy to remedy by rubbing the extrusions with some #0000 Fine Grade Steel Wool, cheaply available at any hardware store.

Rivets Required For Installation: Varies depending on length of section used, as well as associated parts that may be riveted through it.

Depending on your case design some rivets may require backing washers. Most rivets will install through the interior leg of the extrusion and therefore require no backing washers.

Having difficulty determining how much Double Angle Corner you need? The formula is easy and as follows:

Determine the total perimeter distance (circumference) of your case by adding up the width of each of the 4 sides that make up the case and multiply by 2

Example: If you have a trunk style case that is 40" side to side and 20" front to back, your formula would be 40+40+20+20 = 120 x 2 = 240

Then, multiply your case height (top to bottom) by 4

Example: If you have a trunk style case that is 20" high (top to bottom), your formula would be 20 x 4 = 80

THEN, add those two numbers together that you got from your two calculations, divide by 12, and this will give you the total footage required.

Example: 240 + 80 = 320 divided by 12 = 27 feet minimum required double angle extrusion. However, keep in mind that if you don't want to have seams anywhere on your case edges from butting two sections of extrusion together in one corner-to-corner stretch, then you'll need to determine the length of all of your double angle corner extrusion sections, and then purchase enough sticks to yield all of the required length pieces.

And as we always recommend, it's always a good idea to purchase a little more than needed for unforseen errors, plus we rounded our numbers above for ease of understanding, so don't try buying just the exact amount of extrusion for a project. Better to have that extra stick than to run short in the middle of our project, or if you make a bad cut.